Introduction — Why Quality Control Starts Before the Purchase

A single faulty belt can spark online returns, negative reviews, and margin loss. Knowing how to spot quality at the sourcing stage keeps shelves pristine and customers happy. Use this 9-point checklist — distilled from Urban Tuck’s own QC protocol — to evaluate any sample or shipment before you commit.

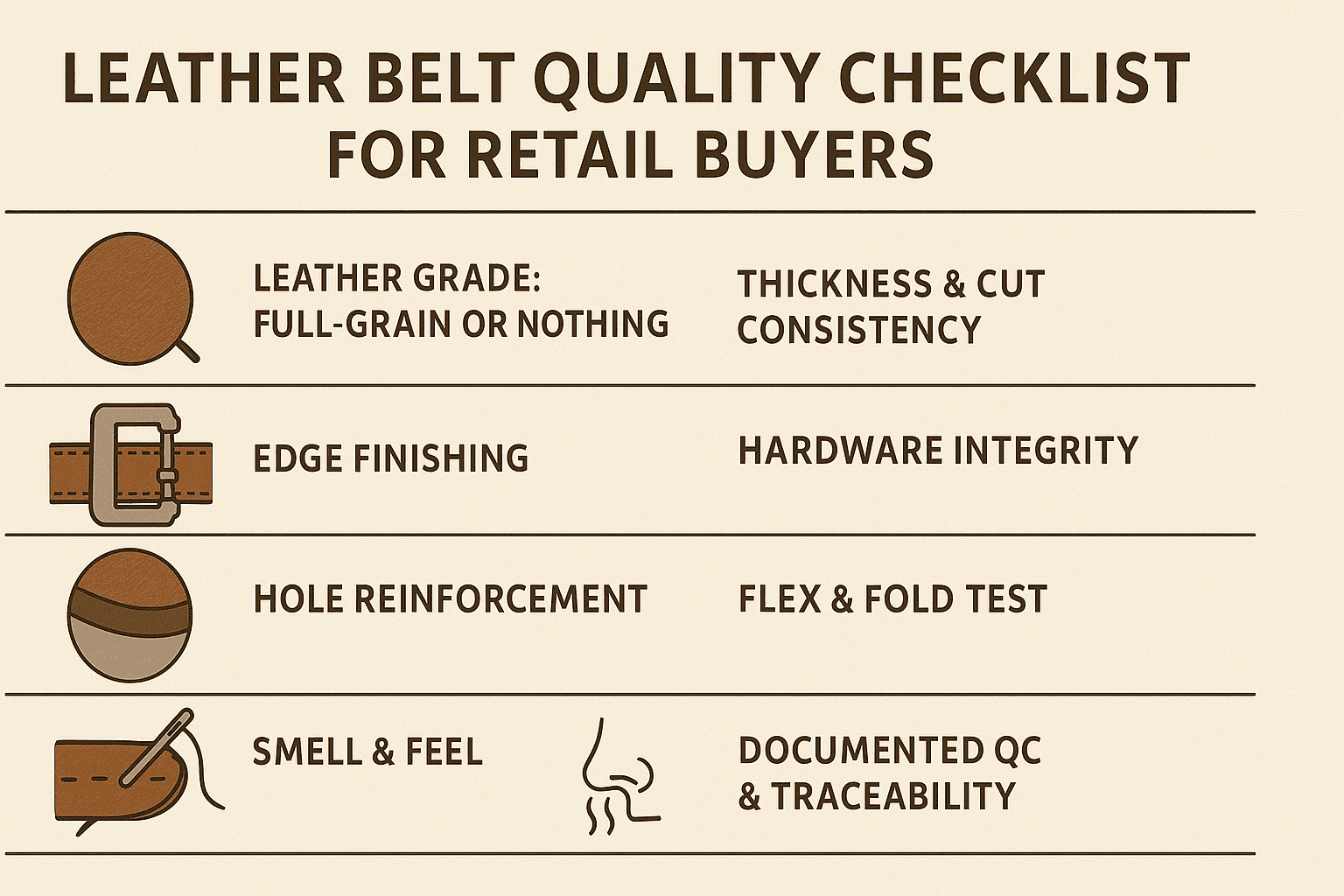

1. Leather Grade: Full-Grain or Nothing

Lift the strap’s edge under bright light. Full-grain leather shows natural pores and subtle grain variation. “Genuine” or split hides feel plasticky and show an even, stamped pattern. Opt for full-grain to guarantee durability and a premium patina over time.

2. Thickness & Cut Consistency

Measure three random spots with a calliper. A tolerance of ± 0.2 mm across the strap prevents weak points near buckle holes. Urban Tuck belts average 3.4 mm thickness with laser-guided cutting for uniformity.

3. Edge Finishing

Run a fingernail along the edge:

- Smooth & sealed – indicates burnishing and wax/paint application.

- Fuzzy fibres – signal hurried sanding and future fraying.

Double-tone edge paint adds visual polish but should never crack when gently flexed.

4. Stitch Density & Tension

Count the stitches per inch (SPI). High-end belts sit around 6–7 SPI with evenly recessed threads. Tug lightly on a single stitch; there should be no slack loops or “ladder” gaps.

5. Hardware Integrity

Unfasten and refasten the buckle five times: the prong must align smoothly without metal burrs. Solid brass or zinc alloy buckles feel cool and weighty; hollow, lightweight frames dent easily.

6. Hole Reinforcement

Pin-holes must be punch-cut cleanly, free of ragged edges. On stress points (first and last holes), look for discreet reinforcement backing or double-stitching to stop tearing.

7. Flex & Fold Test

Bend the belt in a tight “U” for five seconds, grain side out:

- Full-grain shows minimal lightening and no cracking.

- Corrected or coated splits develop visible micro-cracks, a red flag for premature surface peeling.

8. Smell & Feel

Natural full-grain exudes a rich, earthy leather scent — a silent sales driver in-store. Chemical or plastic odours hint at heavy coatings or bonded leather layers.

9. Documented QC & Traceability

Request batch numbers, tanning method certificates, and final inspection reports. Urban Tuck provides REACH, Prop 65, and chrome-VI certificates with each order, plus a three-stage QC log for full transparency.

Quick Reference Table

| Check | Pass Indicators | Fail Indicators |

|---|---|---|

| Grain | Visible pores, unique patterns | Plastic-like emboss |

| Thickness | ± 0.2 mm consistency | Thin spots near holes |

| Edges | Smooth, sealed, no fuzz | Rough fibres, paint cracks |

| Stitching | 6–7 SPI, no loops | Uneven gaps, loose threads |

| Hardware | Solid feel, no burrs | Lightweight, dents easily |

| Hole finish | Clean punch, reinforced | Ragged edges, stretch marks |

| Flex test | No cracks, slight lightening | Surface splitting |

| Smell | Rich, natural leather | Chemical, plastic scent |

| Docs | Certificates, QC log | Missing paperwork |

Conclusion — Quality Sells, Returns Cost

Retail success hinges on products that delight at first touch and last for seasons. By running every prospective belt through the nine checks above, you protect your margin and your brand reputation.